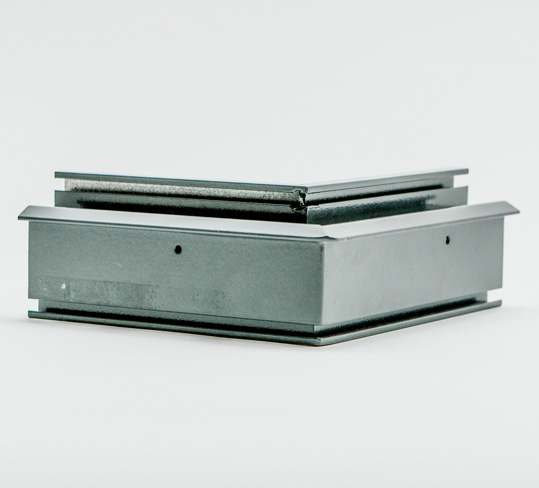

This application incorporates many of the fabrication capabilities that ALMAG has to offer as it requires multiple profiles to be fabricated and assembled together to create a waterproof outdoor frame for drive-thru menu boards. Each frame consists of four miter cut corners that are beveled, fixtured and TIG welded together. The welding on the assembly is then ground to create a sealing surface for a gasket on the waterproof frame. Custom packaging was used to ensure safe delivery of these large custom frames.

Application Category: fabricate

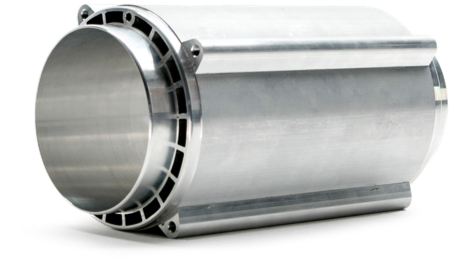

This precision fabricated electric motor housing is cutback and machined on a CNC lathe. The profile presents some challenges with the complexity of the 22 hollows, which are used to cool the electric motor housing assembly. To create a mounting structure for assembly, four extrusions are bonded to the external housing surface using adhesives.

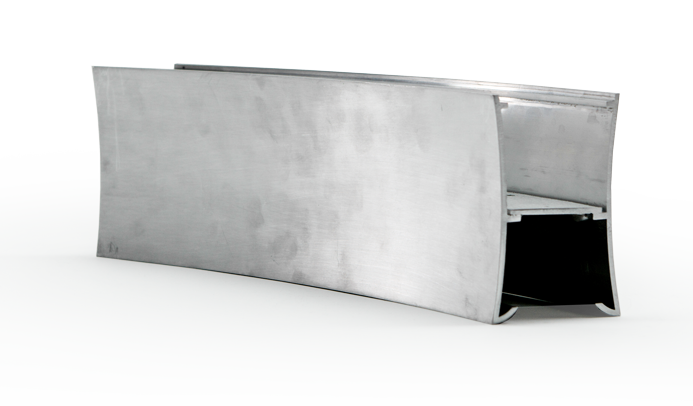

Extrusion is always first produced as a straight linear part, and turning it into a round shape for a bent application is not an easy or simple process. At ALMAG we use our knowledge on materials and tempering of the aluminum alloys to perform secondary operations to the material to achieve precision tolerances on bent shapes. From here, we use custom fixtures to perform multiple downstream operations including cut, weld, and polish for a full seamless 360° look.