Home > Capabilities > Design

Design

At ALMAG, we are not just here to help you create parts, we are here to help you design finished solutions that meet your exact needs. Let us share our expertise across multiple industries and areas of application to help you create a product that sets you apart from your competitors.

Design

Design collaboration from the beginning

We focus on early-stage design collaboration to provide detailed technical guidance and support product development every step of the way.

We start with building an understanding of product form, fit and function, to create designs that optimize key product deliverables. Our experience and engineering capabilities allow us to work with complex and thin-walled applications including multi-cavity hollows, setting new limits of what is achievable in both design and scale. We are able to incorporate multipart designs for applications that require multiple extrusions interfacing with each other.

Rapid prototyping

during testing stage

We understand that designing the right solution or components is a process that requires stages of testing and trial before production begins.

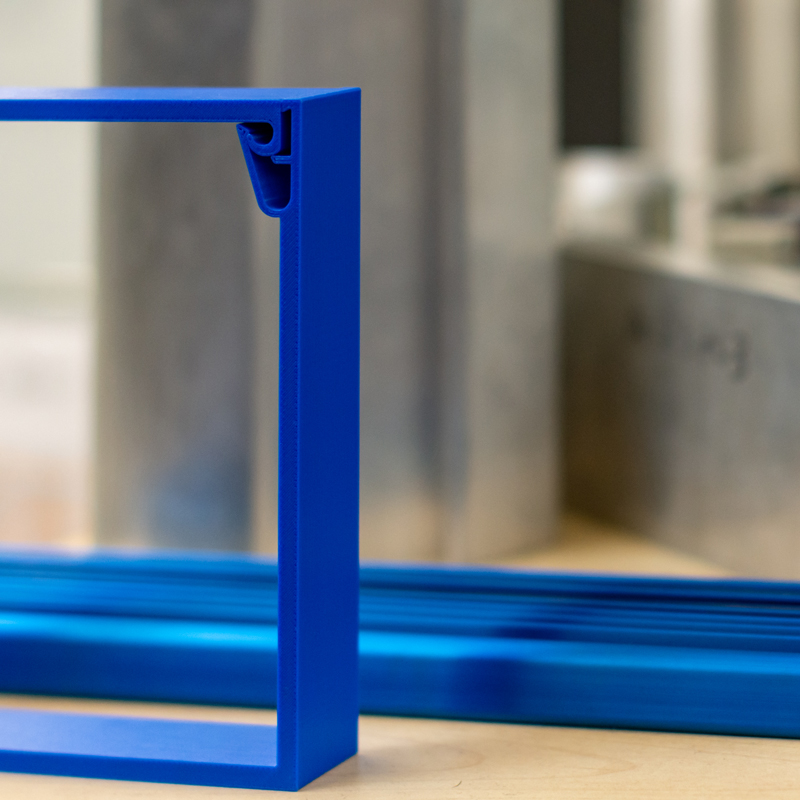

As part of our collaborative design process, ALMAG offers 3D rapid prototyping options. This invaluable tool, used at the beginning of the design process allows our Customers to test-fit parts and get a feel for the product intent before committing to new tooling.

The aluminum advantage

Designing with aluminum has many benefits, and ALMAG maximizes them to your advantage.

High electrical and thermal conductivity which allows for use in applications requiring heat dissipation.

Allows for complex and intricate shapes while maintaining a good strength to weight ratio for products where there are specific weight requirements or restrictions.

100% recyclable and non-toxic, and has a wide range of finishing options where other materials might be limited.

Comparatively low tooling costs and cost-effective production that still allows for high-quality product.

Resists corrosion and maintains uniform quality.

There are many more advantages to designing with aluminum that we take into consideration when helping our Customers achieve the perfect custom solution for their needs.

Eager to find new challenges, we look forward to partnering with you so your next design can be made possible!

We understand that sometimes it takes a little inspiration to get started and see what’s possible. ALMAG’s Inspire tool shows a number of design elements, as well as fabrication and finishing processes, that can be used in a variety of applications. Explore the possibilities and inspire your next design.