Home > Applications > The Wrightspeed Route™ Electric Motor Housing

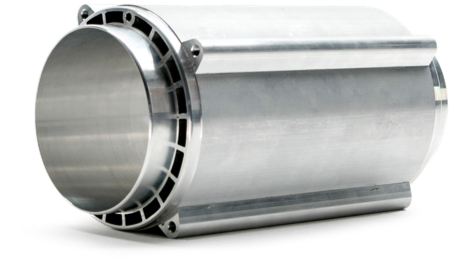

The Wrightspeed Route™ Electric Motor Housing

Light-weighting of vehicles is a major focus of many auto industries especially with Electric Vehicles. The lighter EVs weigh, the more efficient the propulsion and therefore better use of battery life. Developing an EV motor housing that is lightweight, highly engineered, and easy to fabricate and assemble while providing ideal heat dissipation was a collaborative project between Wrightspeed and ALMAG Aluminum.

The end result is the Wrightspeed Route™ Electric Motor Housing. It is a cylindrical motor housing that incorporates many features into its primary function. The 20 hollows surrounding the part allow coolant to flow through the body of the housing providing optimal cooling. With coolant flowing through these 20 hollows it was suggested that serrations be added to the inside diameters of the port increasing the surface area by 12%. These serrations also create a more turbulent flow which contributes to increased heat dissipation.

6063 T65 alloy was selected as it provides and optimal balance of machinability and extrudability. The ID of the large center hollow is honed to precisely fit the electric motor assembly. A second profile is bonded using a structural adhesive to create a mounting feature. Small location tabs were incorporated into the body of the extrusion for assembly ease. These tabs also help with the rotational shear stresses of the part.

This electric motor housing highlights many of the benefits of aluminum extrusion. The EV industry is rapidly growing with new CAFE requirements around the corner. Through the cooperative effort between Wrightspeed and ALMAG, a solution was found. The housing provides structural support to be used within the emerging electrical vehicle market, provides thermal management and can also contribute to green technology.