Inspire Solutions

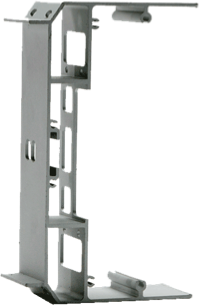

Aluminum extrusion designs allow for great flexibility and involving the ALMAG team early in the design process can save time and money.

Consider all that you need in your part and incorporate as many features as you can. For example, if drilling a screw hole in the part is necessary for assembly of your finished product, consider designing a screw port into the aluminum extrusion. Design features may help save on additional steps and costs down the road.

Guidelines to Help Optimize Your Aluminum Extrusion Design

- Near-net shapes can reduce or eliminate further fabrication operations

- Screw slots and fastening points as part of the design to make final assembly easier

- Tooling costs – aluminum extrusion tooling for solid profiles is less expensive than for hollow or semi-hollow shapes

- Grooves or ribs in your aluminum extrusion can minimize the appearance of scratches or act as stiffeners

- Small radii on corners versus sharp edges

Getting Started with Your Aluminum Extrusion Design

Below is some information to keep in mind when considering your aluminum extrusion whether you’re starting with a new product idea or updating one that’s been around.

- Sketch

- Final Application and Finish

- Aluminum Alloy and Temper

- Critical Dimensions

- Visual Surface

- Secondary Fabrication

- Packaging Requirements

- Quantities

- Cut Length

- Required Time Frame

To learn more about our company, please call 1.888.462.5624,

or send us a note at extrusions@almag.com.

Eager to find new challenges, we look forward to partnering with you so your next design can be made possible!

We understand that sometimes it takes a little inspiration to get started and see what’s possible. ALMAG’s Inspire tool shows a number of design elements, as well as fabrication and finishing processes, that can be used in a variety of applications. Explore the possibilities and inspire your next design.